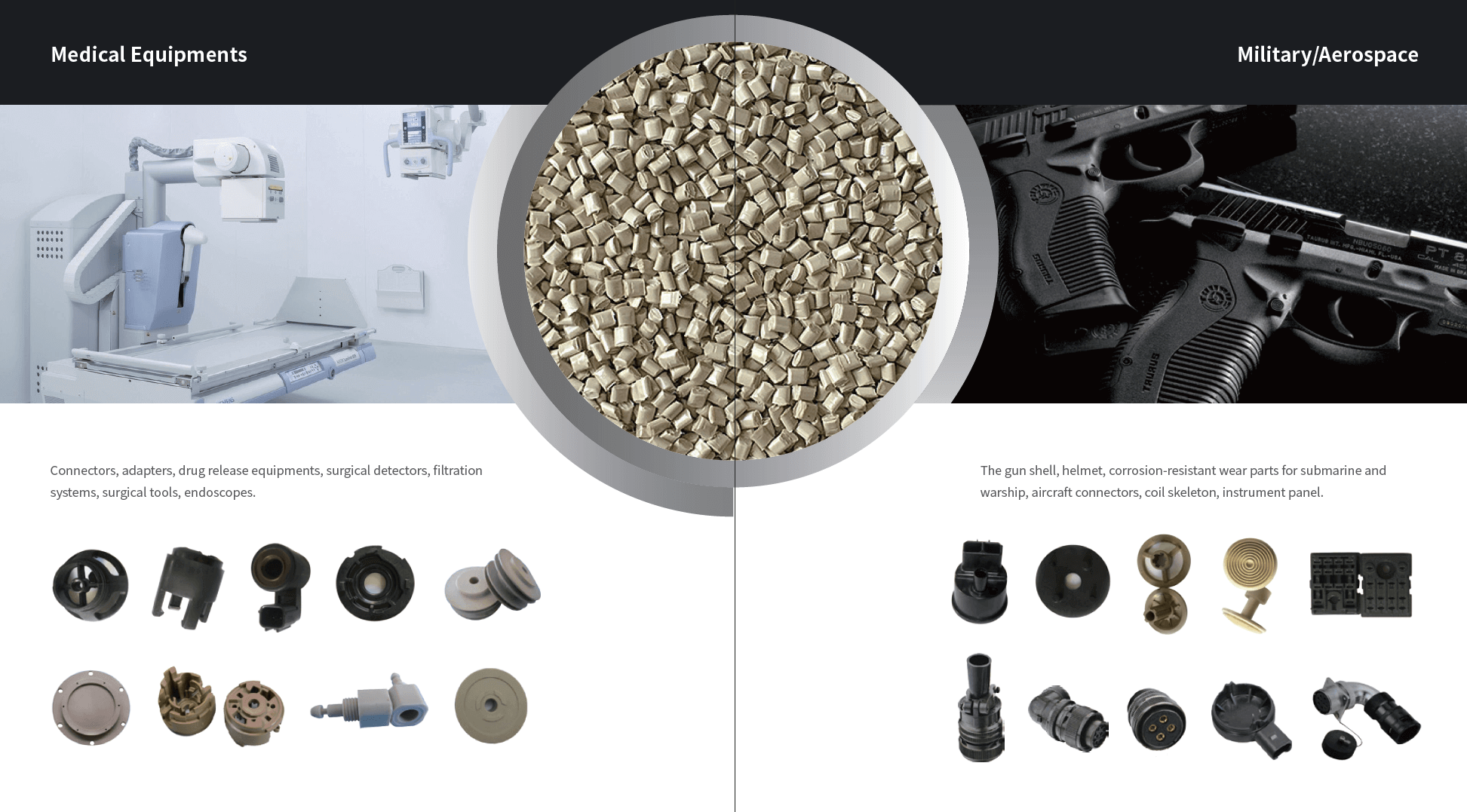

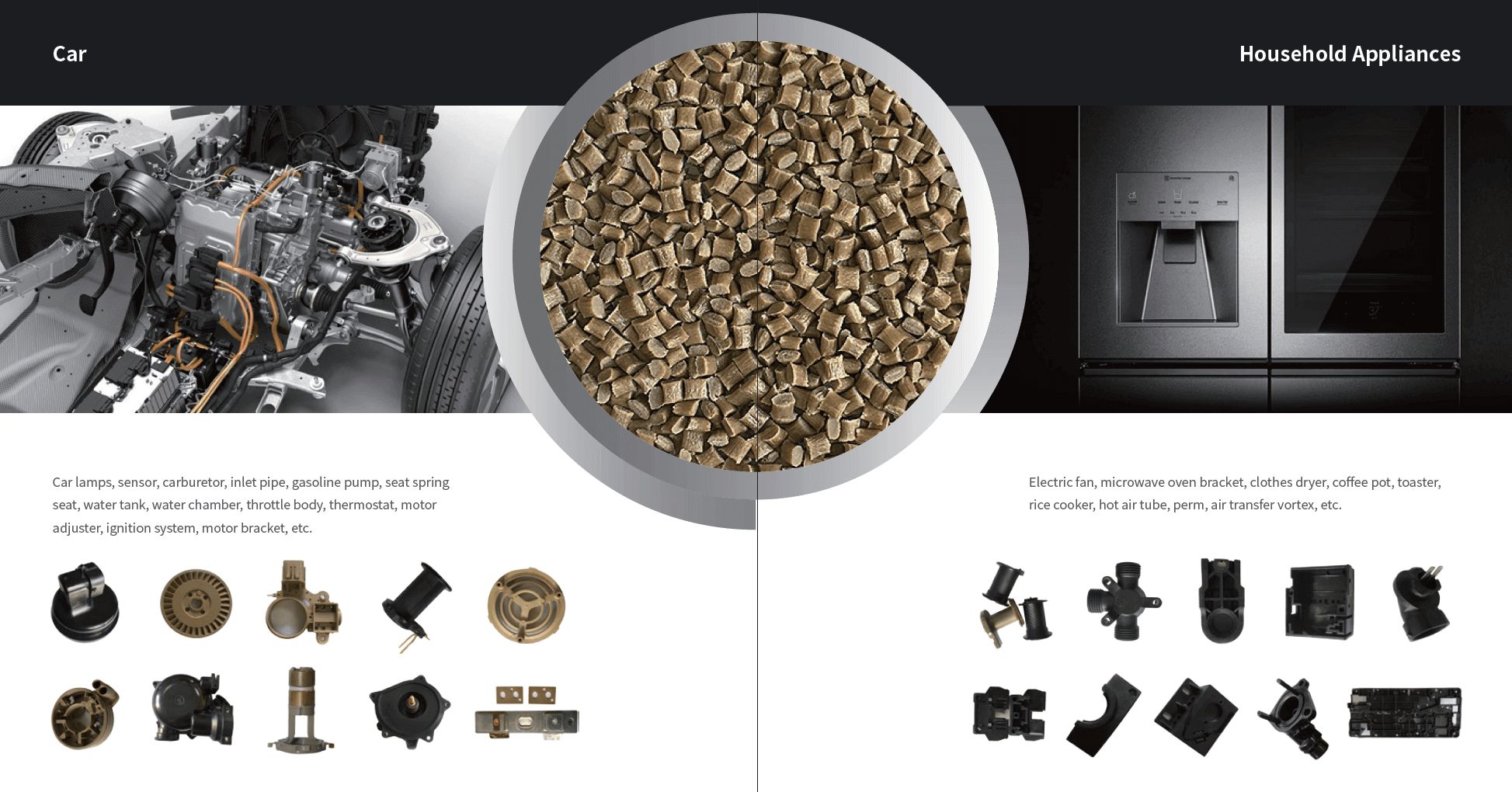

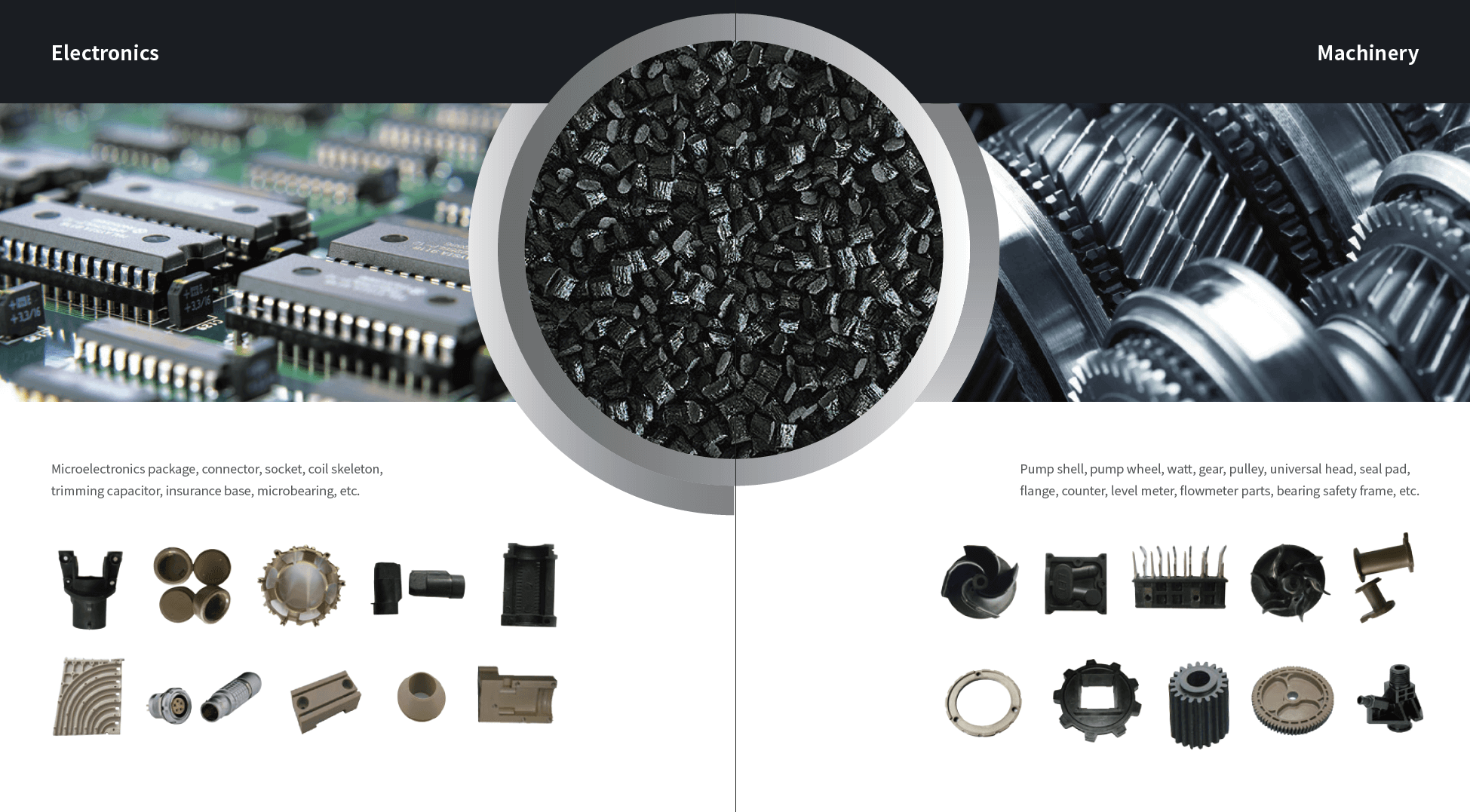

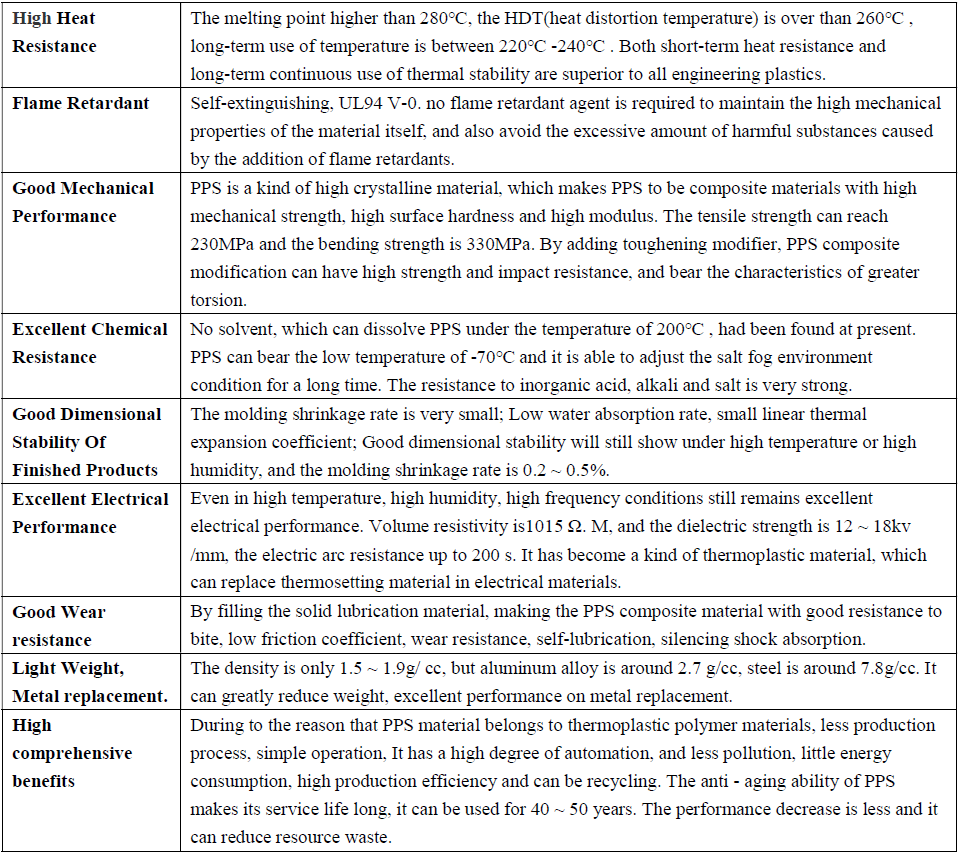

Material plastic Polyphenylene sulfide (PPS) is a new type of high performance thermoplastic polymer with excellent high temperature resistance, corrosion resistance, radiation resistance, flame retardant, balanced mechanical properties, excellent dimensional stability and excellent electrical properties. Due to such excellent performance, PPS composite materials have replaced some metals as structural materials, and are widely used in electronic appliances, automobiles, machinery and chemical engineering, aerospace, military weapons and other fields.

- Email Uskevin@sikopolymers.com