©Copyright 2019 SIKO POLYMERS (SUZHOU) CO., LTD All rights reserved.Site Map Powered by iwonder.cn

- Email Uskevin@sikopolymers.com

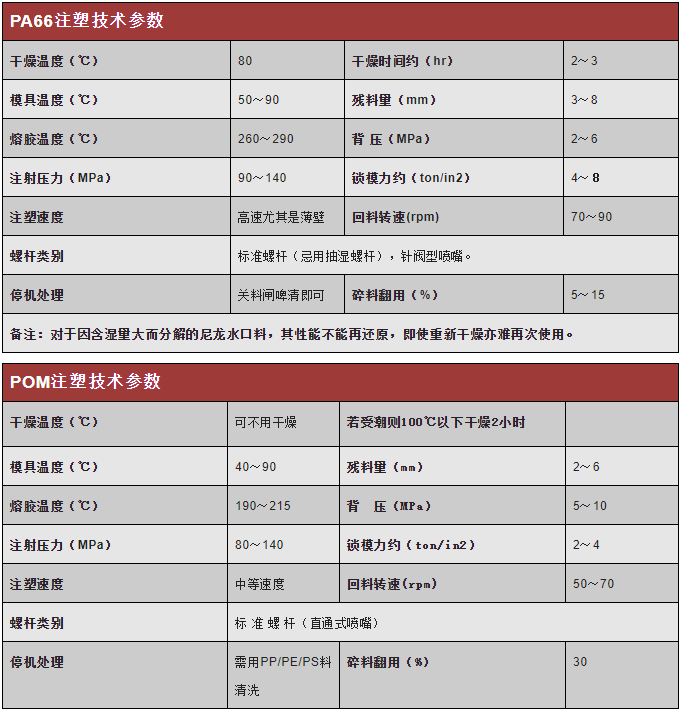

Plastic must be thoroughly dried before forming. After the material containing water enters the mold cavity, the surface of the parts will appear silver sash defect, and even the phenomenon of water decomposition will occur at high temperature, resulting in deterioration of the material. Therefore, the material must be pretreated before forming, so that the material can maintain the appropriate moisture.

For entry-level colleagues, this injection molding parameter details is a good way to remember, for professionals, carry, easy to remember, simple and efficient.

1. Injection pressure

Injection pressure is provided by the hydraulic system of the injection molding machine. The pressure of the hydraulic cylinder is transferred to the injection melt through the screw of the injection molding machine. Driven by the pressure, the plastic melt enters the main channel of the mold from the nozzle and is injected into the mold cavity through the winding mouth.

2. Injection time

Reasonable injection molding time is helpful for filling plastic melt, which is generally about 1/10 of the cooling time. Specific want to press different injection material to decide.

3. Injection temperature

Injection temperature is an important factor affecting injection pressure, injection temperature must be controlled in a reasonable range, low temperature, poor plasticization of raw materials; Raw materials decompose easily at too high a temperature. So the temperature control is the need for experienced master to reasonable control.

4. Holding pressure and time

At the end of injection molding, the screw stops rotating and just pushes forward, entering the pressure holding stage. In the process of holding the pressure, the nozzle continuously adds the raw material melt to the cavity to ensure the integrity of the product after molding. Holding pressure is generally filled with the maximum pressure of 80% or so, according to the requirements of actual raw materials and products.

5. Back pressure

Back pressure refers to the pressure to be overcome when the screw reverses back to store material. High back pressure is conducive to color dispersion and plastic melting.

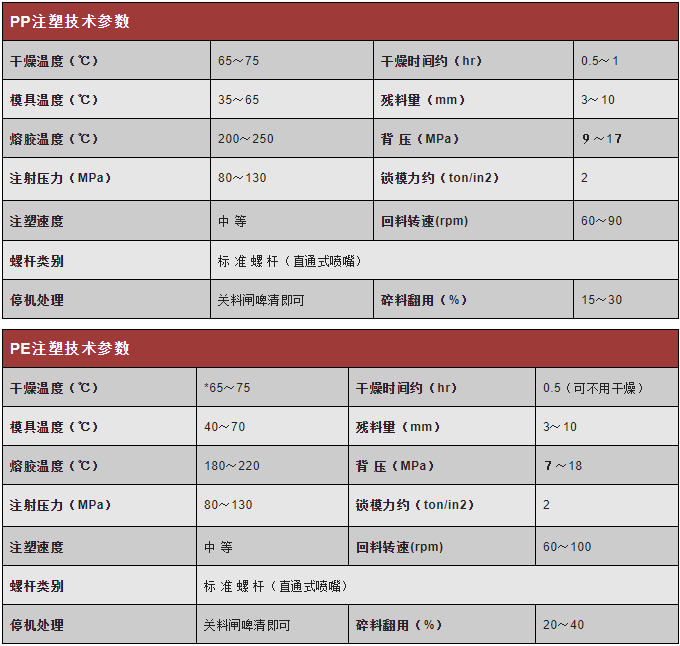

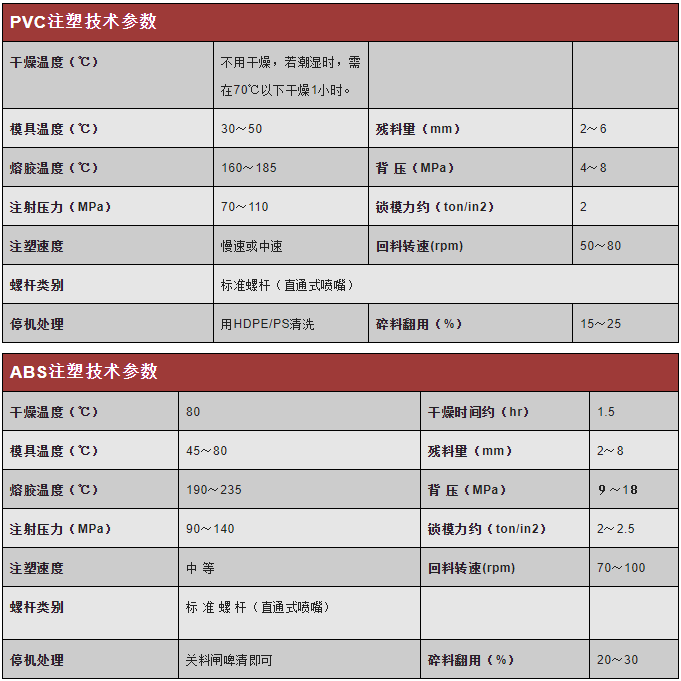

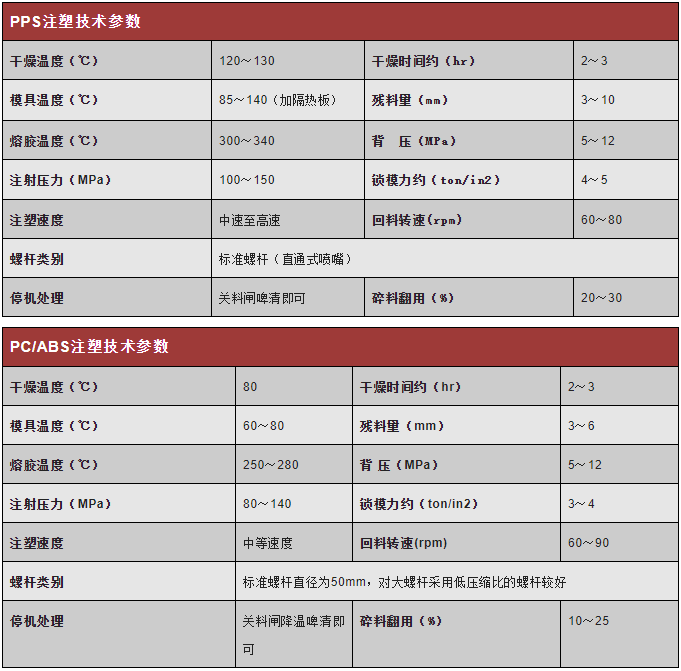

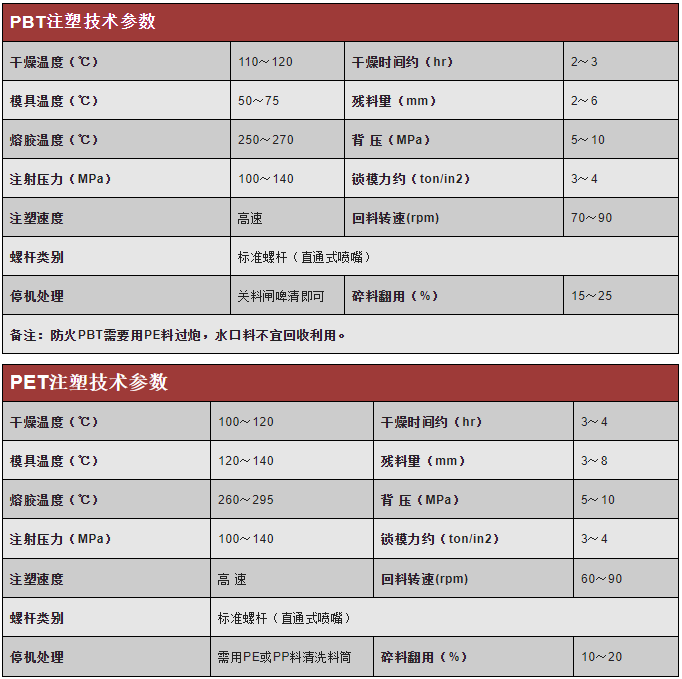

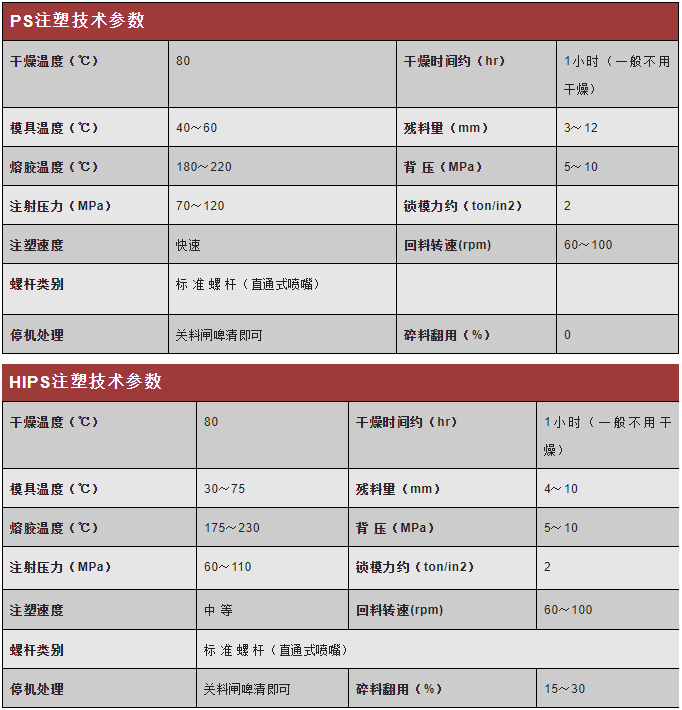

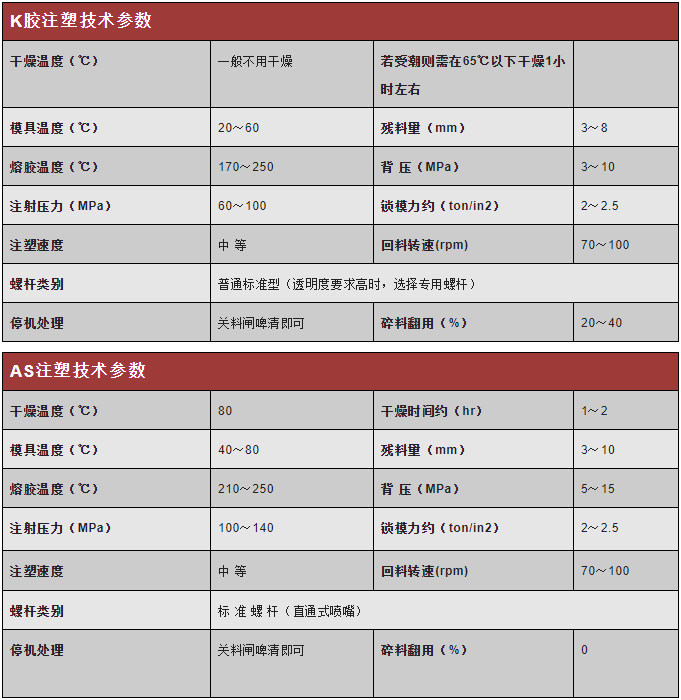

Injection molding parameters of common plastics