©Copyright 2019 SIKO POLYMERS (SUZHOU) CO., LTD All rights reserved.Site Map Powered by iwonder.cn

- Email Uskevin@sikopolymers.com

At present, engineering plastics, aluminum/magnesium/magnesium lithium alloy, carbon fiber composite materials are the most common materials for the pen pen enclosure, as well as minority materials such as glass fiber composite materials, titanium alloy, wood grain or bamboo grain, leather, etc. At present, all plastic laptops account for about 40%, accounting for half of the market. Today, we will talk about engineering plastics commonly used on laptops.

First of all, let's talk about the application classification of plastic in the laptop:

All plastic structure, generally after injection, the surface spray treatment, or directly using IMR injection mold, that is, spray free technology, can save the process of surface treatment. The material of the following C parts is PC+50%GF, and the surface is PU leather after injection molding.

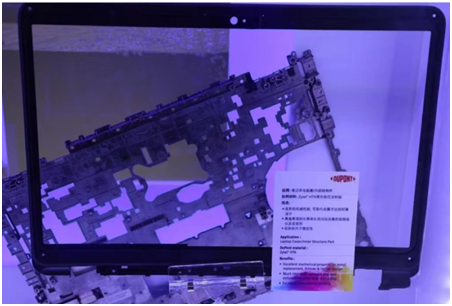

NMT in-mold injection molding is adopted, that is, metal is the main body, and some features such as antenna area and buckle are molded by injection molding. The structural characteristics are similar to those of mobile phone structural parts. As shown below, the white area is magnesium alloy, and the black area is PPS+50%GF.

The following focuses on the common types of plastic materials and their application in the laptop.

1, PC/ABS

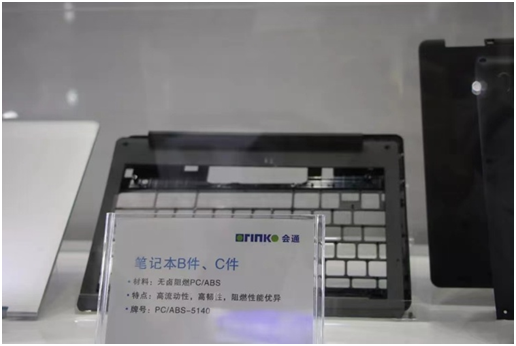

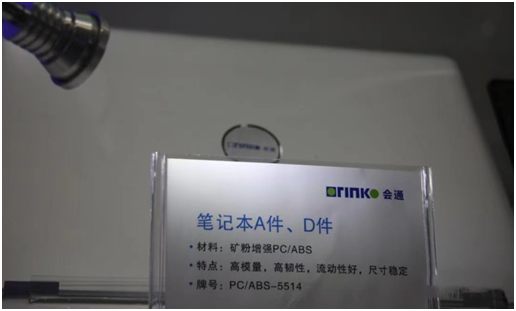

PC/ABS can add glass fiber modification, its mechanical properties, heat resistance to further improve, and can also add mineral powder to enhance, such as adding Talc(Talc) 15 ~ 25%, often used in A/B/C/D pen plastic parts.

Performance characteristics:

(1) Good impact strength, wear resistance, chemical resistance;

(2) Good fluidity, good molding and mechanical processing;

(3) Easy to dye, stable dimensional accuracy.

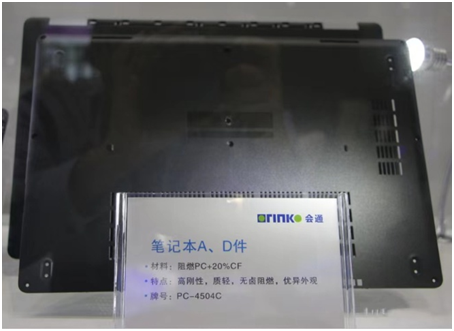

2, the PC + GF

Generally using PC+GF glass fiber strength, its excellent performance, this material is very common on the pen, often used in A/B/C/D plastic parts.

Performance characteristics:

(1) Ultra high notch impact strength;

(2) Excellent mechanical properties;

(3) Stable dimensional accuracy.

3, PPS glass fiber reinforced series

PPS is widely used in electronic and electrical field, such as electric fan, microwave bracket, dryer, coffee pot, toaster, rice cooker, hot air dryer, perm and so on, often used in notebook A/B/C/D plastic parts.

Performance characteristics:

(1) Excellent insulation;

(2) Chemical corrosion resistance;

(3) Dimensional stability.

4, PPA+30% ~ 50% special glass fiber enhancement

PPA is a semi-aromatic polyamide made by polycondensation of diacid containing benzene ring (generally terephthalic acid) and aliphatic diamine, the main varieties are PA4T, PA6T copolymer, PA 9T, PA10T, PA11T, PA12T and so on.

Performance characteristics:

(1) Excellent mechanical properties, can replace metal and achieve thin design;

(2) Low warpage and post deformation can be improved after long-term aging test with high temperature and humidity;

(3) Excellent dimensional stability.

Summary: As mentioned above, the commonly used pen electroplastic parts are made of PC/ABS, PC+GF, PPS, PPA, etc. With the arrival of 5G, 5G notebook develops to lightweight. Whether it is the use of full plastic structure, or the use of metal +NMT injection molding, higher requirements for plastic are put forward. The relevant requirements are as follows:

(1) Low dielectric loss, meet excellent antenna signal transmission function;

(2) Suitable for nano injection molding process;

(3) High strength, low warping, high fluidity, high flame retardant;

(4) Excellent appearance without additional treatment.