©Copyright 2019 SIKO POLYMERS (SUZHOU) CO., LTD All rights reserved.Site Map Powered by iwonder.cn

- Email Uskevin@sikopolymers.com

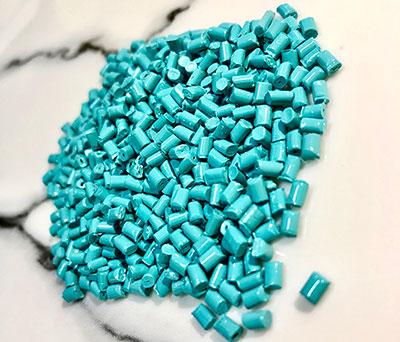

Polymer play key role in nearly every sector of the economy. As the demand for environmentally-friendly and durable plastic increases, key players in the industry adopt technology to meet the demand.

There is steady improvement in the development of engineering plastics. This increases with upgrading in the nature as well as method of production. Besides, engineering plastics have wide temperature range, flexible, chemical stability, better thermal properties, fire safety, and wide uses.

As technology increases, high performance materials like polyphenylenes, polyoxadiazoles, polyperfluorotriazines, and inorganic materials like polysilazanes and boron polymers enter the industry.

Engineering plastics are high performance plastic materials with sustained application in structural uses. It has better chemical resistance as well as resistance to vibration and shock.

Engineering plastics include nylons, phenolics, acetals, fluorocarbons, poly-phenylene oxide, ABS, the urethane elastomers, the acrylics, polyvinyl chloride, and polyolefins.

Engineering plastics are mostly produced in small quantity. Though engineering plastics are strong, generally, they are not as strong as metal. They are also less ductile as metal.

There is steady innovative approach in the production of engineering plastics with required materials. The materials are durable, resistance to chemical, and lightweight.

Moreover, there are machines that produce a reasonable amount of quality engineering plastics. The materials are economical and easy to use for different applications.

Engineering plastics have wide range of applications. Some of the categories of applications are:

Use for couples, cams, gears and other parts. Materials for this application are acetals, polycarbonates, nylons, and fluorocarbons. This is suitable for application such as:

· High impact

· Excellent stability

· Resistance to fatigue

· High temperature

Use for slides, wear surfaces, guides and bearing. Materials for this application are acetals, fluorocarbons, ultra-high molecular polyethylene, and nylon. This is suitable for application such as:

· Good Stability

· Good scratch resistance

· Low friction coefficient

· Heat resistance

· High tensile strength

· Good electrical resistance

· High stability

· High impact resistance

Materials for this are glass-polyester, ABS, cellulose acetate butyrate, and polypropylene. This is suitable for application such as:

· Good strength

· High environmental resistance

· Low cost

Other applications are:

§ Luggage

§ Shoe parts

§ Kitchen utensils

§ Rope

§ Building construction

§ Rollers

§ Furniture

The level of advancement in engineering plastics is increasing every year. This increases the demand in nearly all sectors. Meet a reliable and experienced manufacturer for your quality products.

Kindly contact us for innovative engineering plastics with lightweight at an affordable price. We look forward to partnering with you for a lasting transaction.