©Copyright 2019 SIKO POLYMERS (SUZHOU) CO., LTD All rights reserved.Site Map Powered by iwonder.cn

- Email Uskevin@sikopolymers.com

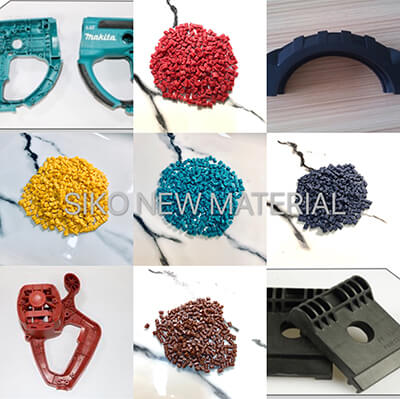

PolyMide PA6-GF is one of the high-performance polymer compounds. It belongs to the Nylon/polyamide family.

It is a filament-based that delivers engineering properties intrinsically to Nylon and also ease of printing.

PA6-GF is a glass fiber-filled material that boasts good strength and stiffness.

Its thermal and mechanical properties are second to none. Wherein it can be used to print at a high-temperature range.

Also, it prints without compromising the layer adhesion. Owing to these excellent properties, it optimizes the surface chemistry of the fibers.

Thus, enhancing dispersion and bonding to the polyamide matrix.

However, for your highly efficient printing materials, you need to source for PA6-GF Manufacturer with reputable and proven performance.

Below are some of the notable technology gap and features of PA6-GF;

Outstanding Technologies of PA6-GF

PA6-GF features two major technology which includes Wrap-free and Fibre Adhesion.

1. Warp-free

Warp-free technology allows the production of Nylon-based filaments that support 3D printing with excellent dimensional stability.

Thus, warp-free provides fine control of the microstructure and crystallization nature of Nylon.

By so doing, it allows the material to fully release the internal stress before solidification.

This technology deployed in PA6-GF is designed to work best with minimal bed temperatures.

2. Fiber Adhesion

Fiber adhesion technology advances the layer adhesion of fiber-reinforced materials.

This results in better strength along the Z-axis and reduced mechanical anisotropy layer adhesion.

Hence, reinforced Nylons, producing a part that is only stronger on the X-Y axis but detrimental to the Z-axis.

All other brands of fiber-reinforced material show a decrease in z-axis layer adhesion when compared with their non-fiber.

Notable Features of PA6-GF

1. Excellent Stiffness and Toughness

PA6-GF is very suitable for high performance industrial and engineering applications. More so, it combines excellent stiffness and toughness,

Owing to this feature, a tensile modulus of 4.4 GPA on the XY axis and 3.3 GPA on the Z-axis are well suited for optimal performance.

2. Excellent Heat Resistance

Heat deflection temperature of about 191o C that is one of the features of PA6-GF can be used to print. In addition, parts will be working in a wide temperature range.

In so doing, it utilized to create custom lab equipment working at temperatures as low as -191°C.

3. Wear Resistant and strong

Print performed with PA6-GF exhibits excellent strength and wear-resistant properties.

4. Improved Printability

Advanced PA6-GF is exceedingly easy to work with when compared to many other Nylon filaments. In so doing, demonstrating excellent dimensional stability.

It is compatible with most filament-based 3D printers, where no heated bed or chamber is required.

5. Uncompromised Quality

PA6-GF Manufacturer ensures quality control and rigorous in-house testing that safeguards reliable printing and consistency across spools and batches.

Conclusion

PA6-GF rapidly expedite that process, while also producing superior and more formative lab equipment.

Based on the above notions, when next you are contemplating of material to use for your 3D printing.

However, don't forget some of the notable technology gap and features that come with PA6-GF.

Thus, all these provide you with useful facts on making the right choice when it comes to the 3D printing material.

Finally, always make sure that you team up with a reliable and professional PA6-GF Manufacturer for the best deal.