©Copyright 2019 SIKO POLYMERS (SUZHOU) CO., LTD All rights reserved.Site Map Powered by iwonder.cn

- Email Uskevin@sikopolymers.com

Introduction:

9

9

PPS is a kind of special engineering plastics with excellent comprehensive performance.

PPS has excellent high temperature resistance, corrosion resistance, radiation resistance, flame retardant, balanced physical and mechanical properties, excellent dimensional stability and excellent electrical properties. PPS is widely used as structural polymer materials, and after being filled and modified, it is widely used as special engineering plastics.

At the same time, it can also be made into various functional films, coatings and composite materials, which have been successfully applied in the fields of electronics, electronics, aerospace, automobile transportation and so on.

Domestic enterprises actively research and development, and initially formed a certain production capacity, changed the past completely dependent on imports.

However, there are still some problems in PPS technology in China, such as fewer product varieties, fewer high-function products, and urgent need to expand production capacity, which will be the focus of PPS development in the next step.

Characteristic:

The outstanding performance of PPS has good heat resistance, thermal deformation temperature is generally more than 260 degrees, can be used in the temperature range of 180~220℃, PPS is one of the best heat resistance varieties in engineering plastics;

Corrosion resistance is close to tetrafluoroethylene, and chemical resistance is second only to polytetrafluoroethylene. Excellent electrical performance; Excellenmechanical properties; Good flame retardant property.

Application:

Electronics: HIGH voltage components, enclosures, sockets, terminals for televisions and computers, motor starting coils, blades, brush brackets and rotor insulation parts, contact switches, relays, electric irons, hair dryers, lamp caps, heaters, F-class films, etc.

Automobile industry: applicable to exhaust recirculation valve and pump impeller, and carburetor, exhaust device, exhaust regulating valve, light reflector, bearing, sensing parts, etc.

Machinery industry: used for bearings, pumps, valves, pistons, precision gears, photocopiers, cameras, computer parts, conduits, sprayers, fuel injectors, instrument parts, etc.

Chemical industry: used for the production of acid-alkali resistant valve pipe, pipe fitting, valve, gasket and submersible pump or impeller and other corrosion-resistant parts.

Engineering plastics: manufacturing automotive parts, anti-corrosion coatings, electrical insulation materials, etc.

Environmental protection field: PPS fiber filter material, applied in smelting, chemical industry, building materials, thermal power, garbage incinerator, coal-fired boilers and other industries under high temperature and harsh working conditions, is a high quality and efficient high temperature resistant filter material.

Tableware: used for making chopsticks, spoons, dishes and other tableware.

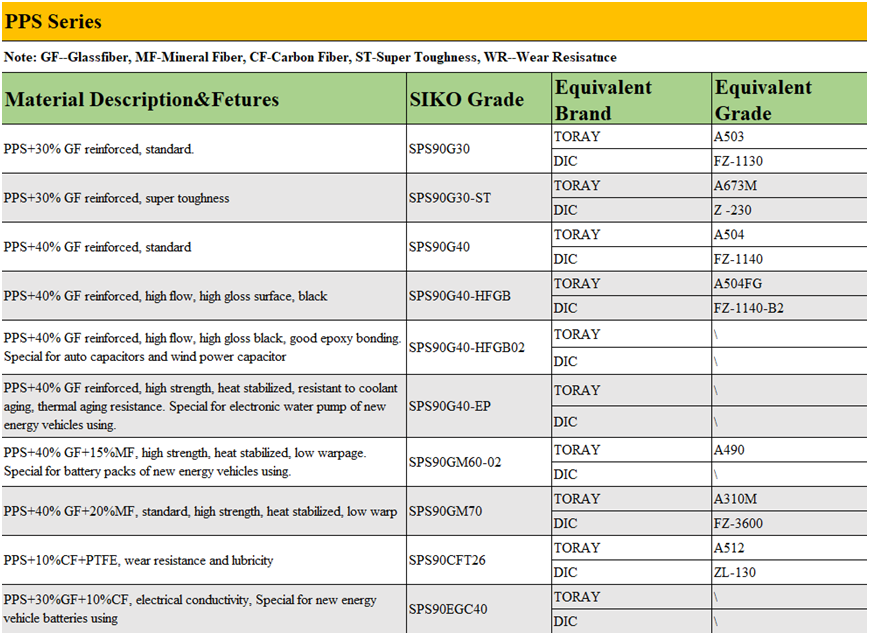

SIKOPOLYMERS’ Main grades of PPS and their equivalent brand and grade, as following: