©Copyright 2019 SIKO POLYMERS (SUZHOU) CO., LTD All rights reserved.Site Map Powered by iwonder.cn

- Email Uskevin@sikopolymers.com

The outbreak of the COVID-19 or coronavirus pneumonia in 2019 has brought unwarranted inconvenience to public health. At the same time, nonwoven bonded fabrics and bulk-producible in masks have come into perspective.

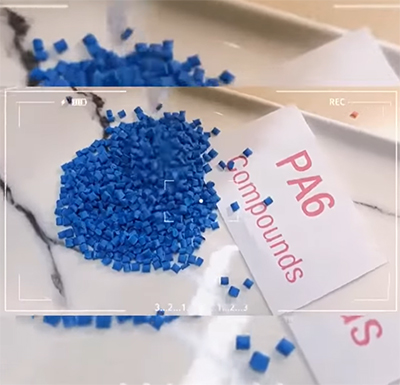

Nonwoven fabrics are considered the best fabrics for masks. Hence, raw materials such as polyamide 6 (PA6) are becoming popular by the day. However, PA6 suppliers assert that, polyamide 6 is one of the ancient materials used in producing nonwoven bonded fabrics.

It upsurges the serviceability of the item for consumption. Also, it improves quality is of impact for many purposes like production of masks, liquid repellency, bacteria barriers, and sterility, etc.

Hence, buying a quality polymer from trusted and reliable PA6 supplier will guarantee great deal.

This article aims at the production and properties of PA6 nonwoven bonded fabrics.

Production of PA6 Nonwoven Bonded Fabrics

PA6 bonded nonwoven fabric is made through a bi-component gyrated bond-gyrated lace procedure. The preparation is summarized into four distinct steps below.

1. Polyamide 6 and polyethylene terephthalate (PET) chips were dropped into vacuum drums at about 120 °C and 60 °C, correspondingly, and allowed to dry for about 5 hours.

2. The dehydrated PA6/PET chip was propelled to the screw extruder to squeeze and melt. Thus, the smelt slurry was directed to melt screen and metering pump in series.

So that all forms of impurities in the smelt slurry are removed. Also, the smelt is delivered to the spinneret evenly and accurately.

3. Then at the spinning equipment, which consists of spinneret and spinning box. The spinneret ensures even dispersal of smelt to each spinning hole for a successive procedure.

A fine stream of polymer smelt is produced from the spinneret holes of the machine. It is cooled beneath the blowing side at the right temperature to form a web.

4. Lastly, the fiber web is directed to the gyrated lace zone after pre-humidification. The fiber web is opened under the exploit of high-vacuum water and ensnared to produce a thicker nonwoven fabric.

The final PA6/PET superfine fiber gyrated bond - gyrated lace nonwoven fabric is obtained after dehydrating and evaporating the wet web fabric.

The product undergoes further treatment by soaking in sodium hydroxide solution to evolve the PET component via an alkaline reduction process.

In other words, PET is dissolved in sodium hydroxide solution, and the insoluble part, which is the PA6 component is left behind.

Properties of PA6 nonwoven bonded fabrics

1. Lightweight

This nonwoven fabric is very light, and its weight is 3/5th of cotton’s weight.

2. Antibacterial

PA6 nonwovens inhibit bacteria growth and corrosion because the material can repel water and is not moldy.

3. Non-irritant and Non-toxic

The PA6 nonwoven fabric is designed to conform to the international standard. Hence, ensuring stability, non-toxicity, and is non-irritating. Due to this unique property, nonwoven fabric is suitable for the production of many lovely products like makeover cotton, facial mask, wet wipes, etc.

4. Air permeability

PA6 bonded nonwoven fabric is produced with 100% fiber, and possess excellent air permeability.

5. Soft

They are made of fine fibers thus, the end product is soft.

Contact Us For Polyamide 6

We are professional PA6 supplier that strive to satisfy our customers' order by offering the fastest technical consulting support and service from the beginning of the project to completion. Kindly click here to enquire about our products and service or order now, and you will be amazed by our services.