©Copyright 2019 SIKO POLYMERS (SUZHOU) CO., LTD All rights reserved.Site Map Powered by iwonder.cn

- Email Uskevin@sikopolymers.com

SIKOPOLYMERS’ grades of biodegradable material and their description and applications, as following:

Material | SIKO Grade No. | Formula System | Main Application |

Biodegradable Blow Film modified material | SPLA-F111 | PLA+ PBAT | Shopping bags, handbags, express bags, garbage bags, rope bags |

SPLA-F112 | PLA+ PBAT+ Starch | ||

SPLA-F113 | PLA+ PBAT+ Mineral Filler | ||

SPLA-F114 | PE+ Starch | ||

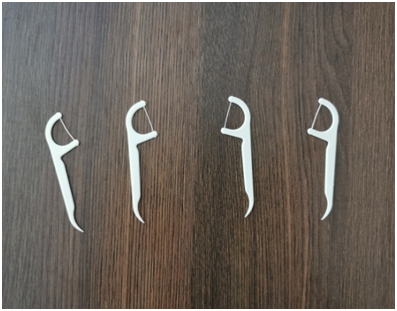

Biodegradable injection molding modified material | SPLA-IM115 | PLA+ PBAT+ Mineral Filler | Table wares like knife, fork, spoon, disposable floss handle, toothpick stick |

Biodegradable blister modified material | SPLA-BL116 | PLA+ PBAT+ Starch | Disposable blister cold and hot meal boxes, trays |

Biodegradable foaming modified material | SPLA-FM117 | PLA+ Cross-linking Agent | Disposable foamed meal box, tray, liner buffer packaging |

Biodegradable 3D printing modified materials | SPLA-3D101 /SPLA-3DC102 | PLA/PLA+ Filler | 3D printing modified materials, 3D printing wire |

Biodegradable film modified material

Mineral powder filled film bag

u Experimental raw materials: PBAT-based, PLA-supplemented, filled with calcium carbonate / talc powder.

u Product description: high stiffness, strength, good heat sealing, printing brush and gloss, meet the requirements of food contact.

u Main applications: shopping bags, garbage bags, express bags, etc.

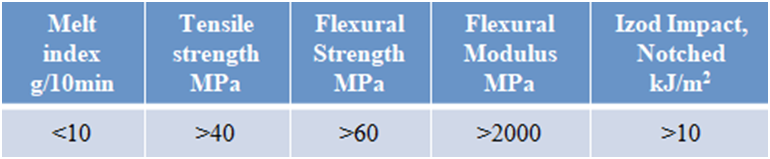

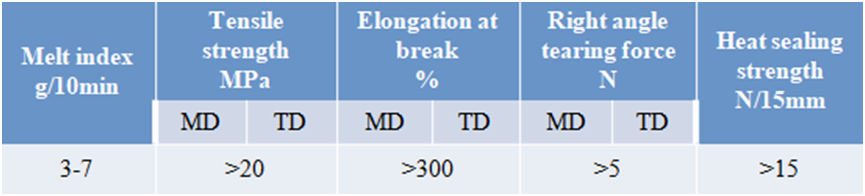

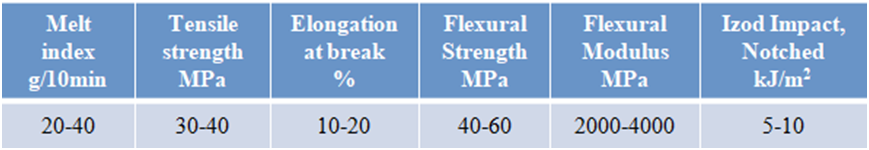

Performance index of the product

Starch filled film bag

u Experimental raw materials: PBAT-based, PLA-supplemented, filled with starch / starch masterbatch.

u Product description: starch is a bio-based, low-cost filler, plasticized by plasticizer and blended with the substrate to achieve complete biodegradation.

u Main applications: shopping bags, garbage bags, express bags and so on.

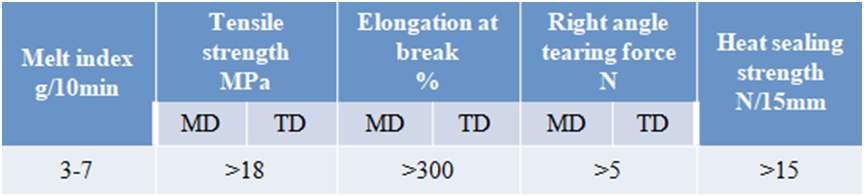

Performance index of the product

Biodegradable injection molding modified material

Mineral powder filled injection molding

u Experimental raw materials: PLA-based, PBAT-supplemented, filled with calcium carbonate / talc powder.

u Product description: high fluidity, high strength, high modulus, high thermal deformation, meet the requirements of food contact.

u Main applications: knife, fork, spoon, dental floss rod, bottle cap and so on.

Performance index of the product

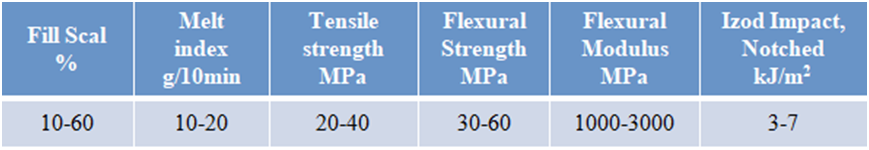

Fiber filled injection molding

u Experimental raw materials: filling plant fiber (rice husk, straw, bamboo fiber, hemp fiber, etc.)

u Product description: the reinforced plastics made of bio-based plant fibers filled with PLA can replace some plastics and other reinforced plastics, can achieve complete biodegradation.

u Main applications: bowls, combs, clothes hangers, etc.

Performance index of the product

Blister cold lunch box

u Experimental raw materials: PLA-based, PBAT-supplemented, filled with talc powder.

u Product description: high melt strength, stiffness and mechanical properties, meet the requirements of food contact..

u Main applications: fruit box, vegetable box, lunch box , etc.

Performance index of the product