©Copyright 2019 SIKO POLYMERS (SUZHOU) CO., LTD All rights reserved.Site Map Powered by iwonder.cn

- Email Uskevin@sikopolymers.com

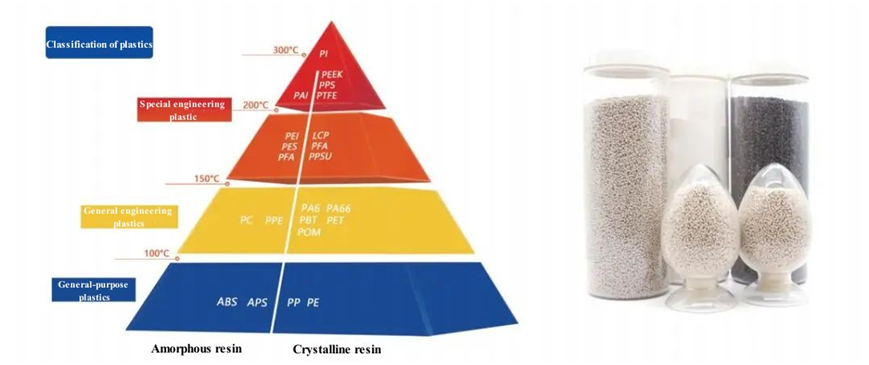

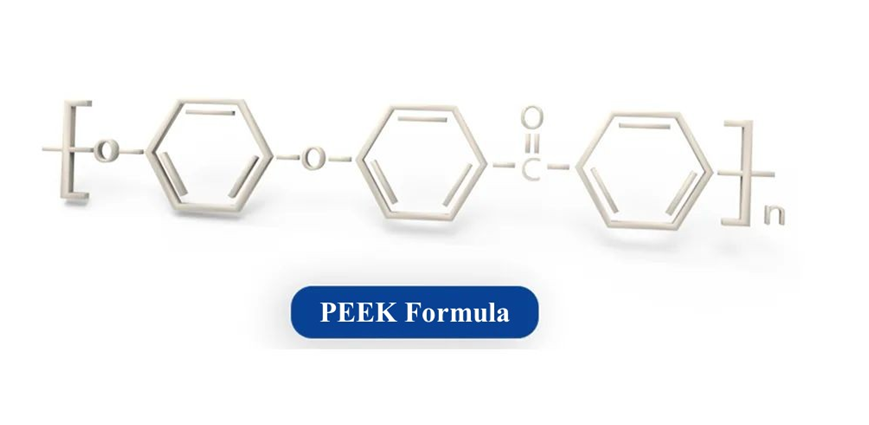

PEEK (poly-ether-ether-ketone) is a special polymer which contains one ketone bond and two ether bonds in the main chain.

Because of its large amount of benzene ring structure, PEEK shows excellent comprehensive properties, such as excellent high temperature resistance, corrosion resistance, good mechanical properties, impact resistance, self-lubrication, flame retardant and so on.

Today, we talk about the advantages of PEEK in terms of high temperature resistance and corrosion resistance.

1. PEEK super high temperature resistance

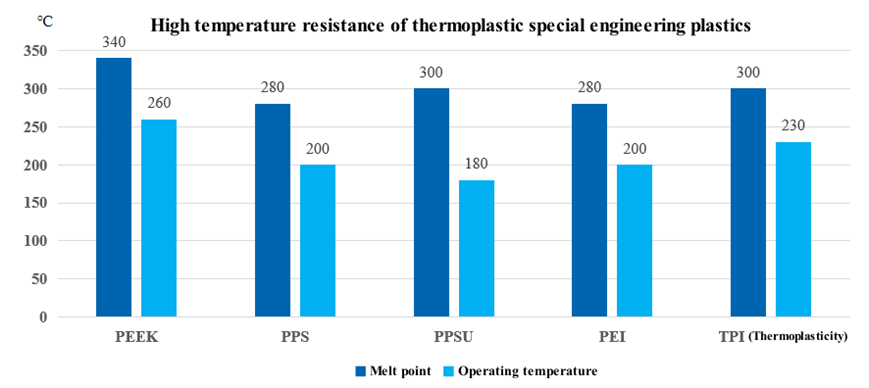

In the petrochemical industry, PEEK material is mainly used because of its high temperature resistance, so what are the advantages of PEEK compared with other thermoplastic special engineering plastics?

Fig 1. Melting point and long-term use temperature diagram of commonly used thermoplastic engineering plastics

From Fig1., we can see that the melting point and long-term service temperature of PEEK are higher than those of the other four thermoplastic special engineering plastics. Therefore, PEEK materials can show excellent heat resistance.

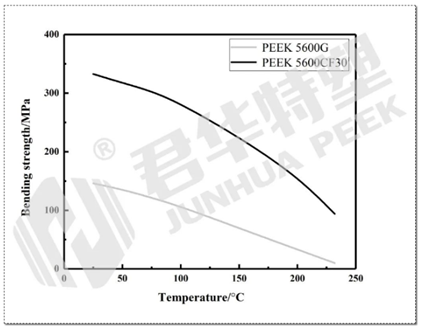

The specific performance of high temperature resistance of PEEK can be tested by high temperature bending and high temperature compression.

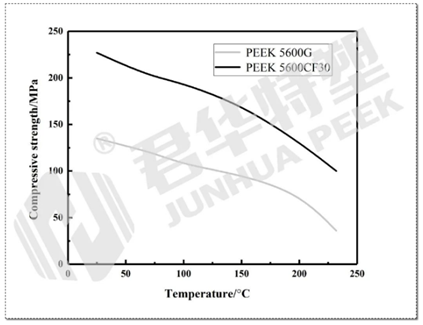

As shown in the following figure:

Fig.2 PEEK5600G and PEEK5600CF30.

High temperature bending property and high temperature compression curve

It can be seen from Fig.2 that, like all plastics, their mechanical properties decrease gradually with the increase of temperature. However, due to the excellent temperature resistance of its PEEK, it can still maintain about 70% of the original performance at 100C.

2. PEEK super corrosion resistance

In the actual production and life, PEEK materials also use corrosion resistance, such as PEEK capillaries for analytical instruments, PEEK joints and so on.

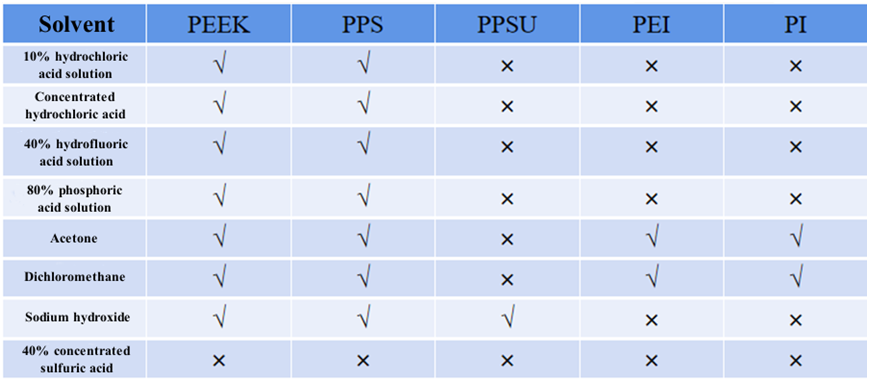

Tab.1 Corrosion resistance tables of several special engineering plastics

It can be seen from Tab.1 that the corrosion resistance of PPS is basically the same as that of PEEK, while the corrosion resistance of PPSU,PEI,PI is worse than that of PEEK.

PEEK products have excellent chemical resistance. In common chemicals, only concentrated sulfuric acid can dissolve or destroy it, and its corrosion resistance is similar to that of nickel steel.