©Copyright 2019 SIKO POLYMERS (SUZHOU) CO., LTD All rights reserved.Site Map Powered by iwonder.cn

- Email Uskevin@sikopolymers.com

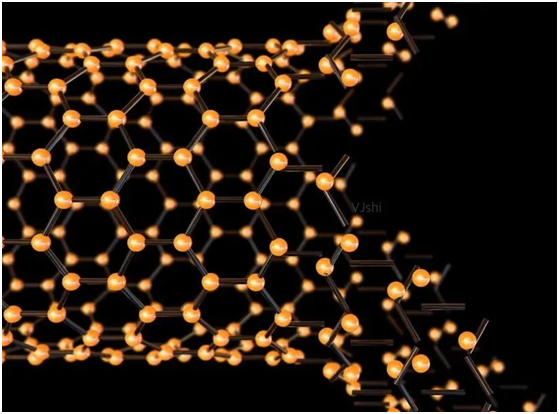

Carbon fiber has the characteristics of high strength, high modulus, high temperature resistance, excellent electrical properties and small volume mass, which not only has the inherent characteristics of carbon materials, but also has the soft processability and excellent mechanical properties of textile fibers. In recent years, it has been widely used in national defense, military, civil and other fields, and it is a high-tech fiber that our country encourages priority development at the present stage.

Foreign countries have realized the industrialization of carbon fiber, but our country is still in the stage of development. As developed countries control as strategic materials, it restricts the development of carbon fiber in our country to a certain extent. Therefore, it is an arduous and urgent task to accelerate the development and production of carbon fiber.

Properties of carbon fiber

The strength is 68 times higher than that of steel, and the elastic modulus is 1.8 to 2.6 times larger than that of steel. The density of carbon fiber is 1 / 4 of that of steel, and the density does not change much even in the manufacture of composite materials. Carbon fiber has small coefficient of thermal expansion, good thermal conductivity, good thermal conductivity, good resistance to high temperature and low temperature, and good resistance to sudden cold and rapid heat. The electrical conductivity of carbon fiber is excellent. The resistivity of high modulus carbon fiber and high strength carbon fiber at 25 ℃ are 7.75 × 10 ~ (- 2) Ω m and 1.5 × 10 ~ (- 1) Ω m respectively. Carbon fiber has good stability, such as strong acid resistance, can withstand the corrosion and impregnation of concentrated hydrochloric acid and sulfuric acid, but also resistant to radiation and can absorb toxic gases.

Carbon fiber has good compatibility with other materials. Carbon fiber has the advantages of light weight, good bending and good processability, so it is suitable for different component shapes. Carbon fiber has a large degree of freedom in design, convenient molding, and can meet the requirements of different product performance. The construction does not need large equipment, the process is simple, and there is no damage to the original structure.

Application of carbon fiber

1. Aerospace

Carbon fiber has a small mass and can save a lot of fuel. It is reported that every 1 kg reduction in the mass of the space shuttle can reduce the launch vehicle by 500 kg. Carbon fiber has certain rigidity and thermal conductivity, so carbon fiber composites have been widely used in missiles, rockets and other aerospace fields. Carbon fiber reinforced resin composites are important materials for the production of weapons and aircraft, which can play an obvious role in weight reduction and improve fatigue and corrosion resistance.

50% of the aircraft materials produced by Boeing use carbon fiber composites and glass fiber reinforced plastics, which can reduce the mass of aircraft without reducing stiffness and strength, saving fuel. If the proportion of carbon materials continues to increase, it will increase flight speed by about 20%. It is predicted that by 2020, only composite materials have the potential to improve the performance of aircraft by 20% to 50%, and the use of carbon fiber composites will reach 65%.

2. Sports

Carbon fiber composites have the characteristics of resin matrix and carbon fiber, and have excellent mechanical properties. therefore, the mechanical properties of carbon fiber composites in sports equipment are much higher than those of traditional wood and its composites.

Carbon fiber is widely used in sports, such as golf clubs, rackets, sailing masts, baseball clubs and so on. The golf club uses carbon fiber to reduce its mass, and the ball can obtain a larger initial speed; at the same time, carbon fiber has a high damping characteristic, so the hitting time increases and the hitting distance of the ball increases. Most of the key parts of advanced bicycles use carbon fiber, which endows the car body with good rigidity and damping performance, and the weight is light.

3. Industry

Carbon fiber is used in household appliances, semiconductors and machine parts to improve strength and protect electromagnetic waves. For example, carbon fiber has become a common material for automobile manufacturing and internal and external decoration, and is widely used in brake pads, engines, tail wings and transmission shafts. the biggest characteristics are high strength, light weight, and the mass is only 20% 30% of that of steel. the hardness is more than 10 times. With the development of the application of carbon fiber in the automobile field, the energy-saving benefit is also very significant.

With the improvement of environmental protection requirements, it is widely used in automobile engine, fuel tank and automobile rear boiling device. Mercedes-Benz sports car body almost all uses carbon fiber composite materials, the weight is light, but the collision energy absorption capacity is very high, not only reduce the weight, improve the speed, but also provide safety protection.

4. Architecture

Carbon fiber is an ideal material for strengthening and anti-seismic of bridges and buildings because of its low density, high strength, good corrosion resistance, good flexibility, good stability and strong strain capacity. it is developing rapidly in industrial and civil buildings, bridges, tunnels and other construction fields.

The framed roof made of carbon fiber can reduce the volume and quality of the building and improve the construction efficiency and earthquake resistance.

5. Energy

As traditional thermal power generation pollutes the environment, people pay more and more attention to wind power generation. Improving the efficiency of wind power generation has always been the goal of wind power generation.

With the progress of science and technology, the traditional glass fiber gradually shows its deficiency in the performance of large composite blades. Glass fiber and carbon fiber composites with good durability, light weight and high strength have become the preferred materials for generator blades. It can improve the wind-catching ability of the blade. Used in the flange parts with high requirements for material strength and stiffness, it can not only improve the bearing capacity of the blade and promote the development of wind power generation, but also avoid lightning damage due to the electrical conductivity of carbon fiber. According to analysis, the use of carbon fiber blades can reduce weight by 20% to 40%.

In addition, carbon fiber is also used in the field of electrochemistry. It is found that carbon fiber can meet the requirements of fuel cells. compared with traditional carbon materials, carbon fiber has the advantages of light weight, small size and high efficiency. Proton exchange membrane diffusion electrode materials made of carbon fiber have been well developed.

6. Medical and health work

Carbon fiber and its composites can be made into artificial limbs and artificial bones, which have stable properties, good biocompatibility and can coexist with human cells. The carbon fiber conductive heating material developed by Yang Xiaoping has the function of auxiliary physiotherapy and health care, which can speed up metabolism, promote blood circulation and accelerate wound healing. Carbon fiber also has X-ray transmission. Changing the wood bed to carbon fiber textile cover during CT scanning can reduce the absorption of X-ray. The X-ray transmission of carbon fiber is 10 times higher than that of wood. With the improvement of medical level, the use of carbon fiber composites in instruments and equipment has a great application prospect.

Future development of carbon fiber

Carbon fiber has many excellent physical and chemical properties and is widely used in production and life. Industrialization has been achieved abroad, but it is still in the stage of research and development in our country.

At present, the task is to break through key technologies, achieve independent innovation, improve production processes, stabilize product quality, and actively develop carbon fiber recycling industry. Adhering to scientific management and realizing the combination of research, production and application can further improve the quality and performance of carbon fiber.

Make great efforts to develop carbon fiber composites, broaden the field of application, and meet the needs of people. At the same time, learn from the experience of foreign countries in the study of carbon fiber and establish relevant mechanisms to make the rapid and healthy development of carbon fiber in China.