©Copyright 2019 SIKO POLYMERS (SUZHOU) CO., LTD All rights reserved.Site Map Powered by iwonder.cn

- Email Uskevin@sikopolymers.com

Since its emergence, plastics have been widely used in various fields of the national economy, such as packaging industry and disposable products industry, which has brought great convenience to human production and life.

However, its huge usage and waste amount have led to increasingly serious environmental pollution, including river pollution, farmland mulch pollution and ocean plastic pollution.

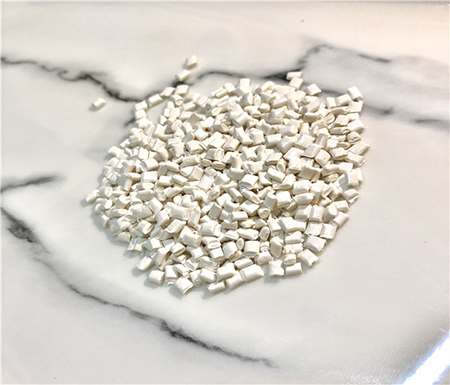

Biodegradable plastic refers to a kind of plastic whose properties meet the requirements of use during the storage period and can be decomposed into environmentally harmless substances in the natural environment after use. It is considered to be one of the effective ways to solve the problem of plastic pollution.

NO. | Product Name | Name abbreviations |

1 | Polylactic acid | PLA |

2 | Polybutanediol succinate | PBS |

3 | Poly(butylenes succinate-co-butylen adipate) | PBSA |

4 | Poly(Butylene Adipate/ Terephthalate) | PBAT |

5 | Polyhydroxyalkanoic or Polyhydroxyalkantotes | PHA |

6 | Carbon dioxide copolymer | PPC |

7 | Poly glycoic acid | PGA |

8 | Polycatrolactone | PCL |

Among them, the PLA, PBS and PBAT have a higher degree of industrialization.

Different biodegradable plastics have different characteristics and advantages and disadvantages.

Under the promotion of the plastic limit order, the degradable plastic industry is very hot, and the major domestic plastic enterprises have expanded production.

It is obvious that the PLA and PBS/PBAT capacity occupy the top position in the market. At present, the global PLA production capacity is 420,000 tons/year, and the capacity under construction or planned to be built is more than 3 million tons.

In order to promote the understanding and understanding of biodegradable plastics, the above biodegradable plastics were compared from the aspects of productivity, comprehensive properties and application fields.

Large-scale production and planning to a certain extent demonstrates that PLA and PBS/PBAT materials are currently the most recognized biodegradable plastics on the market.

In addition, the domestic PLA production technology is obviously lagging behind, especially the lactide raw materials are controlled by others, which leads to the domestic PLA capacity is significantly lower than the foreign PLA capacity.

PHA, PPC, PGA, such as photo degradable plastics existing capacity and the future is expected to increase capacity is small, the main reason is that this kind of biodegradable plastic is still in the primary stage of industrialization, mature production technology, production cost is too high, the market recognition is not high, the stage with the PLA and PBS/PBAT compete in alternative general plastic, but more for high-end biomedical materials field.

Polyethylene (PE) is a widely used traditional plastic and the main substitute of biodegradable plastics. PE has excellent crystallinity, water vapor barrier and weather resistance, which can be collectively referred to as "PE characteristics".

In fact, currently common biodegradable plastics are basically aliphatic polyesters, such as PLA and PBS, which can be roughly regarded as PE with ester bonds. The ester bonds in its molecular chain give it biodegradability, and the aliphatic chain gives it "PE characteristics".

The melting point and mechanical properties of PBAT and PBS are similar to those of PE, indicating that they can basically cover the application of PE in disposable products industry.

However, the other varieties have disadvantages such as poor mechanical properties, poor heat resistance, rapid degradation and high cost, which need to be further improved before large-scale application.