©Copyright 2019 SIKO POLYMERS (SUZHOU) CO., LTD All rights reserved.Site Map Powered by iwonder.cn

- Email Uskevin@sikopolymers.com

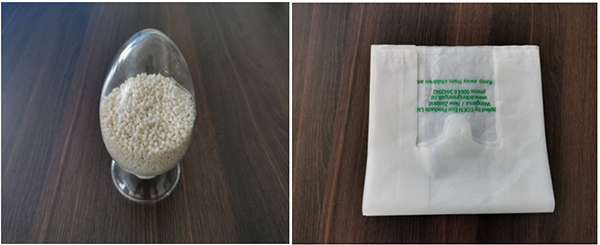

Biodegradable film modified material-BF1111

【Product Description】

The main components of BF111 products are PLA and PBAT, and their products can be 100% biodegraded after use and waste, and ultimately generate carbon dioxide and water, without polluting the environment. The product has good processing and physical properties, and can be directly used for blown film processing to make various film products. The physical properties and use performance of the final product are close to or exceed those of similar traditional plastic products.

【Application Field】

It can completely replace traditional plastic packaging bags, such as shopping bags, handbags, express bags, garbage bags, drawstring bags, etc.

【Processing Instructions】

When using BF1111 blown film on the blown film production line, the recommended blowing film processing temperature is 140-160

performance | The test method | unit | data |

Density | ISO 1183 | g/cm3 | 1.29 |

Melt index | ISO 1133 (200oC,2.16kg) | g/10min | 8.7 |

The tensile modulus | ISO 527 | MPa | 242 |

The tensile strength | ISO 527 | MPa | 19.5 |

Elongation at break | ISO527 | % | 500NB |

Biodegradable film modified material-BF1112

【Product Description】

The main components of BF1112 products are PLA, PBAT and starch, and its products can be 100% biodegraded after use and discard, and ultimately generate carbon dioxide and water without polluting the environment. This type of product is relatively cheap due to the large proportion of starch added, its mechanical properties and use can meet the requirements of conventional packaging film materials, and the degradation rate is fast and the price is low. The product has good processing and physical properties, and can be directly used for blown film processing to make various film products.

【Application Field】

Shopping bags, handbags, express bags, garbage bags, drawstring bags, etc.

【Processing Instructions】

When using BF1112 blown film in blown film production line, the recommended blowing film processing temperature is 140-160℃.

performance | The test method | unit | data |

Density | ISO 1183 | g/cm3 | 1.30 |

Melt index | ISO 1133 (200oC,2.16kg) | g/10min | 7.48 |

The tensile modulus | ISO 527 | MPa | 205.5 |

The tensile strength | ISO 527 | MPa | 14.8 |

Elongation at break | ISO527 | % | 500NB |

Biodegradable film modified material-BF1113

【Product Description】

The main components of BF1113 products are PLA, PBAT and inorganic substances. The products can be 100% biodegraded after use and discarded, and eventually generate carbon dioxide and water without polluting the environment. Because this type of product is filled with a large proportion of inorganic substances, its price is relatively cheap, its mechanical properties and use can meet the requirements of conventional packaging film materials, and its degradation rate is fast and the price is low. The product has good processing and physical properties, and can be directly used for blown film processing to make various film products.

【Application Field】

Shopping bags, handbags, express bags, garbage bags, drawstring bags, etc.

【Processing Instructions】

When using BF1113 blown film in blown film production line, the recommended blowing film processing temperature is 140-165℃.

performance | The test method | unit | data |

Density | ISO 1183 | g/cm3 | 1.43 |

Melt index | ISO 1133 (200oC,2.16kg) | g/10min | 2.9 |

The tensile modulus | ISO 527 | MPa | 203.5 |

The tensile strength | ISO 527 | MPa | 20.0 |

Elongation at break | ISO527 | % | 316.4 |

Biodegradable film modified material-BF1114

【Product Description】

The main components of BF1112 products are PLA, PBAT and starch, and its products can be 100% biodegraded after use and discard, and ultimately generate carbon dioxide and water without polluting the environment. This type of product is relatively cheap due to the large proportion of starch added, its mechanical properties and use can meet the requirements of conventional packaging film materials, and the degradation rate is fast and the price is low. The product has good processing and physical properties, and can be directly used for blown film processing to make various film products.

【Application Field】

Shopping bags, handbags, express bags, garbage bags, drawstring bags, etc.

【Processing Instructions】

When using BF1112 blown film in blown film production line, the recommended blowing film processing temperature is 140-160℃.

performance | The test method | unit | data |

Density | ISO 1183 | g/cm3 | 1.30 |

Melt index | ISO 1133 (200oC,2.16kg) | g/10min | 7.48 |

The tensile modulus | ISO 527 | MPa | 205.5 |

The tensile strength | ISO 527 | MPa | 14.8 |

Elongation at break | ISO527 | % | 500NB |

Biodegradable injection molding modified material

【Product Description】

The main components of the product are PLA, PBAT and inorganic substances, and its products can be 100% biodegraded after use and waste, and ultimately generate carbon dioxide and water, without polluting the environment. This type of product has good melt fluidity and high mechanical strength, and is especially suitable for injection molding. It can produce multi-cavity products with a short cooling time, low price, and fast degradation. The product has good processing and physical properties, and can be directly used for injection molding to make various molded products.

【Application field】

Disposable dental floss handles, interdental brushes, tooth picking sticks, toothbrush handles, rice bag handles, hangers, etc.

【Processing Instructions】

When using this product for injection molding, it is recommended that the injection processing temperature be 180-195°C. When the mold is cooled by a chiller, the production cycle of a mold with 20 cavities is about 23 seconds.

Biodegradable blister modified material

【Product Description】

The main components of the product are PLA, PBAT and inorganic substances, and its products can be 100% biodegraded after use and waste, and ultimately generate carbon dioxide and water, without polluting the environment. This type of product has high melt strength and low melt index, and is especially suitable for sheet extrusion processing and applications in the blister box industry. The product has the characteristics of stable melting finger, high melt strength, good processing performance and excellent mechanical properties.

【Application Field】

It can be directly used in fully biodegradable disposable blister hot and cold lunch boxes and trays, and can be directly extruded to make business cards, cards, etc.

【Processing Instructions】

When using the modified product on an extruded sheet production line, the recommended extrusion processing temperature is 180-200℃.

performance | The test method | unit | Non heat resistant | Heat resistant |

Melt index | ISO 1133-A(200oC,2.16kg) | g/10min | 6.5 | 54.5 |

Thermal deformation temperature | ISO 75-1.2 | oC | 52 | 119 |

The tensile modulus | ISO 527-1,2 | MPa | 2764 | 3542 |

The tensile strength | ISO 527-1,2 | MPa | 41.9 | 57.0 |

Elongation at break | ISO 527-1,2 | % | 65 | 1 |

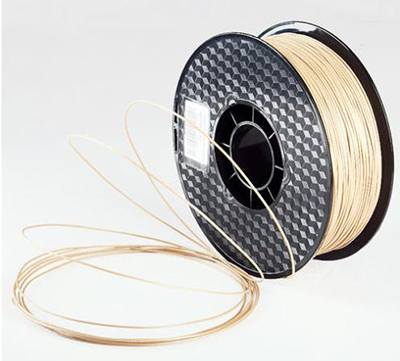

Biodegradable 3D printing modified material

High toughness, high strength 3D printing modified material

Low-cost, high-strength 3D printing modified materials

PLA3D printing wire

Product Certification

【Foreign】

DIN CERTCO certification and OK Compost certification, according to the European standard EN13432 for biodegradability and compostability, France, Belgium, Italy and others prefer OK compost, and Germany and the Netherlands prefer DIN CERTCO certification.

Cost and cycle: If the product is made of certified materials (European and American certification), the cost is 20,000 RMB 20,000 and the cycle is about 1 month;

If the product is made of new raw materials (without European and American

certification), the cost is about 100,000 yuan, and the cycle is more than half a year.

【Domestic】

Third-party testing institutions such as the National Plastic Products Testing Center, Feifan Testing, and Stand Testing can test. According to the standard GB/T 19277.1, the final aerobic biodegradability of materials under controlled composting conditions is determined. Third-party testing does not issue certificates. Only provide test report, only applicable to domestic customers.

Cost and cycle: The cost is about RMB 20,000, and the test cycle is 45 days (generally can meet the standard). If the standard requirement is not met after 45 days of the test, it needs to extend the cycle (30 days). The cost is about 5,000 yuan, the longest It can be done for 180 days.

Future product direction-foamed products

Ø PLA foaming principle: PLA foaming is the use of physical foaming to prepare foam. The principle is to use a physical foaming agent to fully mix with PLA under a certain temperature and pressure to achieve equilibrium saturation. Then, the foaming gas and PLA The mixture of the melt undergoes thermodynamic state and changes, and saturated gas molecules escape from the melt, resulting in a foam structure with a certain pore size and density, thereby forming a PLA foam.

Ø The expansion ratio of PLA extruded foam sheet is 10-40 times, 10-20 times can be used to produce lunch boxes and trays, and 20-40 times can be used for shock absorption packaging.

Ø At present, the best one in China is Guangdong Bijia Material Technology Co., Ltd. Its material has high melt strength and is suitable for extrusion foaming process. Its products are widely used in disposable foamed lunch boxes, trays, and cushion packaging.

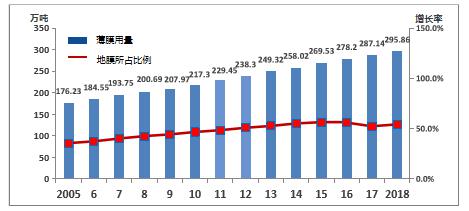

Future product direction-mulch products

Ø China is a large agricultural country. At present, the annual investment in mulching film is about 1.5 million tons, covering an area of more than 350 million mu, and the residual film rate of farmland is about 40%. The degradation cycle of mulch film is generally 200~300 years. Long-term accumulation of mulch residues in farmland will affect crop yields.

Ø Studies have shown that when the residual film content in the soil is 58.5kg/hm2, the yield of corn will be reduced by 11% to 23%, wheat yield will be reduced by 9%-16%, soybean yield will be reduced by 5.5%-9%, and vegetable yield will be reduced by 14.6%-59.2%.

Ø National standard "GB/T35795-2017 Fully Biodegradable Agricultural Ground Cover Film".

The consumption of agricultural film and the proportion of mulch film nationwide from 2005 to 2018

Future product direction-fiber products

Ø China is a major producer of chemical fiber. In 2018, the total output of chemical fiber is expected to reach 52.6 million tons, accounting for 70% of the world's total chemical fiber output. 90% of chemical fibers are petroleum-based synthetic fibers, which are greatly restricted by petroleum resources.

Ø The performance of PLA fiber is similar to those of general fiber, and it has the advantages of biodegradation, bacteriostasis, better UV resistance, flame retardant and barrier property, etc. Differentiated and functional PLA fiber is expected to be applied on a large scale.

Future product direction-engineering plastics

Ø From the perspective of long-term use,we try to modify the PLA and apply it to the fields of electronic and electrical products, office automation, communication materials and automobile interior accessories. For example, Foxconn in Japan modified PLA with polycarbonate (PC), and the PLA/PC blend obtained by injection molding products are used in computer keyboards, computer casings, Walkman casings, DVD panels and CD.

Ø The modified PLA has good performance of impact resistance, heat resistance, rigidity and flame retardancy, etc. It has been widely used in the manufacture of computer parts, portable notebook shell, mobile phone parts, DVD player shell, CD, home appliance parts, auto parts and so on.

Making a diligent search for the best product might be a great task that is demanding and challenging sometimes. We are aware of this and that is why we are reaching out to you with the best quality biodegradable plastics. Kindly click here to check out and order your high-quality injection PPO products and you will be glad you did.