©Copyright 2019 SIKO POLYMERS (SUZHOU) CO., LTD All rights reserved.Site Map Powered by iwonder.cn

- Email Uskevin@sikopolymers.com

Polymer porous material is a polymer material with numerous pores formed by gas dispersed in the polymer material.

This special porous structure is very good for the application of sound-absorbing materials, separation and adsorption, drug sustained release, bone scaffold and other fields.

Traditional porous materials, such as polypropylene and polyurethane, are not easy to be degraded and take petroleum as raw materials, which will cause environmental pollution.

Therefore, people began to study biodegradable open-hole materials.

Application of PLA open-hole material:

PLA open-hole material also has some disadvantages, which limit its application in the field of open-hole material, such as:

1. Crisp texture, low tensile strength and lack of elasticity of the perforated material.

2. Slow degradation rate.

If left in the body for a long time as a drug, it can cause inflammation.

3. Drain.

Low affinity for cells, if made into artificial bone or scaffold cells are difficult to adhere and proliferate.

In order to improve the shortcomings of PLA open-hole materials, blending, filling, copolymerization and other methods were adopted to improve PLA open-hole materials.

The following are several modification schemes of PLA:

1. PLA/PCL blending modification

PCL, or polycaprolactone, is also a biodegradable material with good biocompatibility, toughness and tensile strength.

Blending with PLA can effectively improve the toughness tensile strength of PLA.

The researchers found that the properties could be controlled by controlling the ratio of PCL to PLA. When the mass ratio of PLA to PCL was 7:3, the tensile strength and modulus of the material were higher.

However, the toughness decreases with the increase of pore diameter.

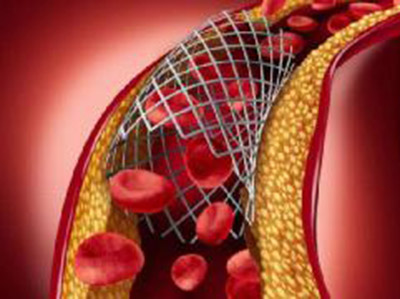

The PLA/PCL material is non-toxic and has potential applications in small diameter vascular tissues.

2. PLA/PBAT blend modification

PBAT is a degradable material, which has the degradability of aliphatic polyester and the toughness of aromatic polyester. The brittleness of PLA can be improved after blending with PLA.

The research shows that with the increase of PBAT content, the porosity of the open-hole material decreases (the porosity is the highest when PBAT content is 20%), and the fracture elongation increases.

Interestingly, although the addition of PBAT reduces the tensile strength of PLA, the tensile strength of PLA still increases when it is processed into open-hole material.

3. PLA/PBS blending modification

PBS is a biodegradable material, which has good mechanical properties, excellent heat resistance, flexibility and processing ability, and is very close to PP and ABS materials.

Blending PBS with PLA can improve the brittleness and processability of PLA.

According to the research, when the mass ratio of PLA: PBS was 8:2, the comprehensive effect was the best; if the PBS was added in excess, the porosity of the open-hole material would be reduced.

4. PLA/ BIOactive glass (BG) filling modification

As a bioactive glass material, BG is mainly composed of silicon sodium calcium phosphorus oxide, which can improve the mechanical properties and bioactivity of PLA.

With the increase of BG content, the tensile modulus of the open-hole material increased, but the tensile strength and elongation at break decreased.

When the BG content is 10%, the porosity of the open-hole material is the highest (87.3%).

When the BG content reaches 20%, the compressive strength of the composite is the highest.

Moreover, the PLA/BG composite porous material can deposit osteoid apatite layer on the surface and inside in simulated body fluids, which can induce bone regeneration. Therefore, PLA/BG has the potential to be applied in bone graft materials.

The level of advancement of PLA open-hole material and engineering plastics is increasing every year. This has increased demand in almost all industries. Meet with reliable and experienced manufacturers to obtain quality products.