©Copyright 2019 SIKO POLYMERS (SUZHOU) CO., LTD All rights reserved.Site Map Powered by iwonder.cn

- Email Uskevin@sikopolymers.com

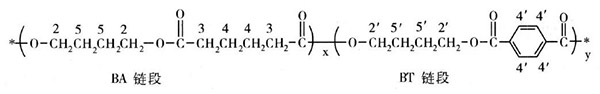

PBAT is a copolymer of aliphatic polyester (PBA) and aromatic polyester (PBT). Therefore, PBAT has the advantages of both, including good biodegradability, as well as good mechanical properties and processing properties.

Basic performance of PBAT

The degradation period of PBAT is very short. PBAT agricultural film produced by Xinjiang Lanshan Tunhe Chemical Industry Co., Ltd. is used for experiments in corn fields with abundant rainfall in the south. It can be completely degraded within 16 weeks, and the degradation period is less than half a year in relatively dry environment.

The only products of degradation are water and carbon dioxide.

Compared with LDPE, the traditional packaging material, PBAT has better mechanical properties, the impact resistance is 130% of POLYETHYLENE, the tensile property is 120% of polyethylene, and the processing method is very simple.

Therefore, it is very hopeful to replace the traditional polyethylene, become degradable environmental protection packaging materials.

However, PBAT itself also has some disadvantages, such as poor film opening performance, poor film blowing stability and high cost.

By blending with PBS, starch, PLA and other materials, these problems can be greatly improved.

PBAT has soft texture and strong toughness, and some brittle materials are usually added to complement each other.

The market structure of PBAT

PBAT is one of the most active biodegradable materials in biodegradable plastics research and market application.

The most representative is the PBAT material produced by Germany's BASF.

China's PBAT industry has developed very well, and its research level takes a leading position in the world. Moreover, its downstream raw materials are provided with sufficient supply and its production lines are complete.

PBAT is a high molecular compound synthesized based on fossil fuels, so it is more abundant than other biodegradable plastic raw materials that need plant fiber and starch.

The main raw materials of PBAT are PTA, 1, 4-butanediol and adipic acid.

The synthesis process of these three raw materials has been very mature in China and is in the stage of overcapacity.

Therefore, raw material conditions for PBAT development are good, and the further expansion of PBAT will help to improve the problem of upstream raw material overcapacity.

Not only is the raw material condition good, its production technology is also relatively mature.

The production device of PBAT is very similar to that of PBT, PET and PBS. China has rich experience in r&d and production of PET and PBT, which can be easily applied to the production of PBAT.

At present, the world's PBAT production is still insufficient to supply the expanding market demand.

China began to invest heavily in PBAT degradable materials, and many manufacturers expanded production one after another, which further reduced production costs.

It is expected that the PBAT market will expand at an annual rate of 15% in the future, and PBAT products will become regular customers in our life.

The application of the PBAT

Usually used to make degradable packaging bags, garbage bags, plastic film, plastic wrap, etc.