©Copyright 2019 SIKO POLYMERS (SUZHOU) CO., LTD All rights reserved.Site Map Powered by iwonder.cn

- Email Uskevin@sikopolymers.com

Two key points of new energy vehicles: power battery and lightweight

At present, the automotive industry reform in the early stage is mainly electric. During this period, the core components of the car are no longer the "three big pieces" (engine, gearbox and chassis), but the three electrical systems (battery, motor and electronic control), which account for more than 50% of the cost of new energy vehicles. Among them, the cost of power battery accounted for 90% of the cost of three electricity. Therefore, the power battery system can be called the "heart" of new energy vehicles.

The lightweight of new energy vehicles is mainly related to electronics-related materials, such as connectors, charging interfaces, power battery peripheral materials, etc. Under the condition that the performance meets the requirements, the metal is replaced by plastic, which can reduce the weight by about 30%. At present, a pure electric vehicle using lightweight plastic can reduce the weight of about 100KG.

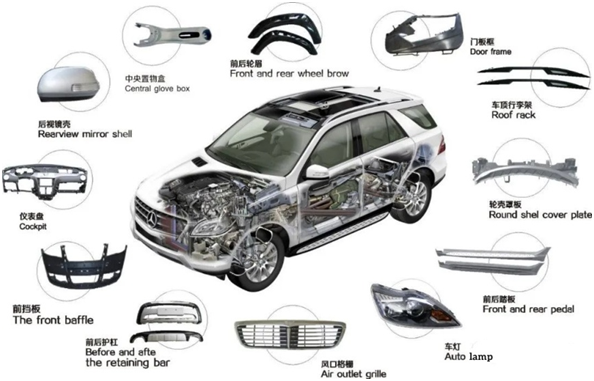

The use scenario of engineering plastics for new energy vehicles combined with automotive products needs to meet the following performance requirements:

Chemical corrosion resistance, oil resistance, high and low temperature resistance;

Excellent mechanical properties, high fluidity, excellent processing performance;

Excellent surface performance, good dimensional stability;

With good waterproof, moisture-proof, flame retardant, environmental performance and heat conduction function;

Good dielectric resistance, suitable for electrical places;

Good weather resistance, good long-term performance, can be used in harsh environment for a long time.

Power battery system

1. Power battery support

Power battery support requires flame retardant, size stability, chemical resistance, high strength, currently mainly used modified PPE, PPS, PC/ABS, etc

2. Power battery cover

Power battery cover requires flame retardant, size stability, chemical resistance, high strength, currently mainly used modified PPS, PA6, PA66, etc.

3. Power battery box

The power battery box requires flame retardant, size stability, chemical resistance, high strength, currently mainly used modified PPS, modified PP, PPO, etc.

4. DC motor skeleton

DC motor skeleton mainly uses modified PBT, PPS, PA.

5. Relay housing

Performance and automotive electronic relay housing mainly uses modified PBT.

6. The connector

New energy vehicle connectors mainly use modified PPS, PBT, PA66, PA

Motor drive system and cooling system

1. The IGBT module

IGBT module is the core component of electronic control system and DC charging pile of new energy vehicles, which determines the energy utilization rate of the vehicle. In addition to the traditional metal and ceramic materials, PPS engineering plastics are gradually applied.

2. Car water pump

Electronic pump rotor, pump shell, impeller, water valve and other requirements of high toughness, high wear resistance, high strength, the main use of modified PPS material.

Here are 4 common engineering plastics

1, PA

Polyamide, commonly known as nylon, industrial use of PA more kinds, commonly used PA6, PA66 and PA610. Due to the influence of thermal expansion and water absorption, the dimensional stability of the parts is poor, and the shrinkage rate is 1 ~ 2%. It is necessary to pay attention to the size change of moisture absorption after forming. Water absorption rate of 100%, relative moisture absorption saturation can absorb 8%, suitable wall thickness: 2 ~ 3.5mm.

PA in the automotive field is mainly used in the manufacture of hose (brake hose, fuel pipe), combustion oil filter, air filter, oil filter, pump housing, pump impeller, fan, brake fluid tank, power steering fluid tank, white leaf window, headlight housing, seat belt.

2, PMMA

Polymethacrylate, commonly known as organic glass, outdoor aging resistance, excellent light transmission suitable plastic products: transparent structure with certain strength requirements.

PMMA is widely used in automotive lighting signs, door glass and lamp glass cover because of its good light transmission performance.

3, POM

Polyformaldehyde, commonly known as plastic steel, shrinkage rate of 2-3.5% suitable wall thickness: 1.5-2.5mm.

POM in the automobile with the manufacture of instrument panel glove box accessories, all kinds of valves (drainage valve, air conditioner valve, etc.), all kinds of impeller (water pump impeller, heater impeller, oil pump wheel, etc.), all kinds of electrical switches and electrical instruments on the pinion, all kinds of handle and door pin, etc.

4, PC

Polycarbonate, with outstanding impact toughness and creep resistance, good heat resistance, cold resistance is also good. The shrinkage rate is 0.5-0.7%, and the appropriate wall thickness is 2-3.5mm. PC added to glass fiber can improve its shrinkage, mechanical strength and temperature resistance, at 100℃ or so long-term use of steel will increase, can be annealed to improve the internal stress.

Introduction to the main synthetic PC-ABS:

Pc-abs is a blend of PC and ABS material, usually to blend material, in the shape of grain supply. If only the two materials are simply mixed, direct injection molding, the effect is very poor, there will be stratification phenomenon; The advantages of PC are tough and tough, the disadvantage is stress cracking, viscosity; The advantages of ABS are good fluidity, but low surface hardness; In this way, the blended material PC-ABS retains the advantages of both; PC-ABS has high surface hardness, high rigidity and toughness, and high stress cracking resistance; Its mechanical properties are somewhere in between.

PC in the automotive field is mainly used in the manufacture of lampshade, left and right wheel cover plate, instrument baffle body (PC+ABS), left and right wind frame cover, middle wind frame cover (PC+ABS), rear bumper cushion.