©Copyright 2019 SIKO POLYMERS (SUZHOU) CO., LTD All rights reserved.Site Map Powered by iwonder.cn

- Email Uskevin@sikopolymers.com

With the rapid development of the automobile industry, especially the rapid development of new energy vehicles in recent years, the demand for light weight, integration, miniaturization and electrification of auto parts is also increasing. In the field of new energy, the lightweight of the body and battery can effectively improve the cruising range and energy utilization of new energy vehicles. Therefore, lightweight is one of the main directions of future automotive technology development.

Replacing some metals with plastics can reduce weight by about 30%, provided the performance is met. SIKO has long produced high-performance polyamides for metal replacement materials for customers, which are characterized by high strength, water and oil resistant, high surface, hydrolysis resistant, high temperature resistance.

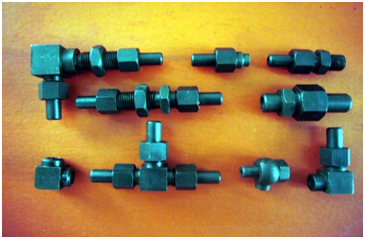

High strength, water and oil resistant products

Made of stainless steel Made by SIKO PPA

High strength, high surface, hydrolysis resistant product

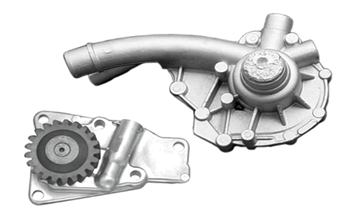

Made of metal Made of PA, PPA glass fiber reinforced materials

High strength, oil and temperature resistance products

Made of cuprum Made of PPA reinforced material

With the excellent performance of high-performance polyamide materials and the rich experience in the field of replacing steel with plastics, while assisting in development, it helps customers reduce technological processes and improve production efficiency, and more and more commercial vehicle customers get A more cost-effective lightweight solution.