©Copyright 2019 SIKO POLYMERS (SUZHOU) CO., LTD All rights reserved.Site Map Powered by iwonder.cn

- Email Uskevin@sikopolymers.com

SIKO’s high performance PPA composite material are widely used to manufacture high precision, high temperature resistant and high strength products. Especially for automotive engine peripheral products, which need to cope with increasingly stringent aging requirements, high-temperature nylon has gradually become the best choice for automotive engine peripheral materials.

Automotive high-performance reinforcement materials have excellent balanced properties such as:

Excellent mechanical properties, high strength, high toughness

Ø Excellent hydrolysis resistance, high mechanical properties after long-term soaking in hot and cold water

Ø Excellent refrigerant resistance, meet the automotive material refrigerant resistance test standard

Ø High-gloss surface, no floating fiber on the surface of 35-40%GF reinforced material, high brightness

Ø Meet the requirements of environmental protection, good dimensional stability

SIKO typical successful applications in automotive field:

Supercharger end cover (intercooler)

Material Grade: PPA+35%GF Material requirements : - Excellent thermal aging performance - Excellent oil resistance - Excellent hydrolysis resistance - Good product surface

|

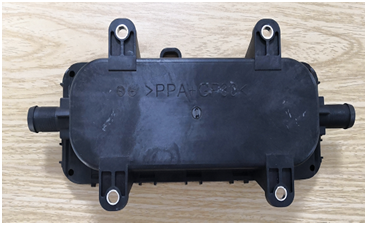

Auto Thermostat Housing Material Grade :PPA+35%GF Material requirements : - Hydrolysis resistance (ethylene glycol - antifreeze resistance) - Excellent mechanical properties (no cracking when riveting) - High and low temperature resistant - Dimensional stability

|

Auto Seat Heater Material Grade : PPA+30%GF

Material requirements : - Excellent high and low temperature resistance - High dimensional stability - Excellent weather resistance - Long term high temperature thermal aging resistance

|

In addition, high temperature nylon also has a wide range of applications in Electronic and Electrical Engineering, Machinery industry, Industrial Consumer and Medical instruments.