©Copyright 2019 SIKO POLYMERS (SUZHOU) CO., LTD All rights reserved.Site Map Powered by iwonder.cn

- Email Uskevin@sikopolymers.com

Some people thought that replacing metal with PPS plastic would reduce product quality. Actually, the use of PPS metal replacement can improve product quality in many occasions.

PPS material has the advantages of high temperature resistance, high strength,high modulus, high heat resistance, wear-resistance, chemical-resistance, creep resistance, dimensional stability and so on. It can replace stainless steel, copper, aluminum, alloys and other metals, and is considered to be the best replacement for metals. In recent years, the scope of application of polyphenylene sulfide has been expanding, and it has been widely used in electronics, electrical, automotive, construction, machinery, new energy, transportation and other industries, and replacing steel with plastic has become an international trend.

Why PPS excellent on metal replacement?

PPS plastic is a rising star. It not only retains the excellent characteristics of ordinary plastics, but also has higher temperature resistance and mechanical strength than ordinary plastics.

1. High performance

Modified PPS plastic is one of the best varieties of engineering plastics with high temperature resistance, and its thermal deformation temperature is generally above 260 °C. In addition, it also has the advantages of small molding shrinkage, low water absorption, excellent fire resistance, vibration fatigue resistance, strong arc resistance, etc., especially in high temperature and high humidity environments, it still has excellent electrical insulation, so it can be used in Many application areas replace metals as engineering materials.

2. Lightweight product

The specific gravity of ordinary PPS plastic is about 1.34~2.0, which is only 1/9~1/4 of steel and about 1/2 of aluminum. This property of PPS is especially important for mechanical equipment such as vehicles, boats, and airplanes that need to be reduced in weight.

3. High strength

For the same volume of material, the strength of PPS is usually lower than that of metal, but because PPS is much lighter than metal, when compared with the same weight of metal, PPS is much stronger than ordinary metal. Among existing structural materials, it has the highest intensity.

4. Easy to process

PPS products are often formed at one time, while metal products generally have to go through several, a dozen, or even dozens of processes to complete. This feature of PPS is very important to save working time and increase productivity. The machining of plastics is relatively simple. Plastic products are widely used in the automobile industry, which are mainly used to replace various non-ferrous metals and alloy materials, which not only improve the aesthetics of automobile modeling and the flexibility of planning, but also reduce the cost of parts processing, assembly and maintenance. It can also reduce the energy consumption of the car.

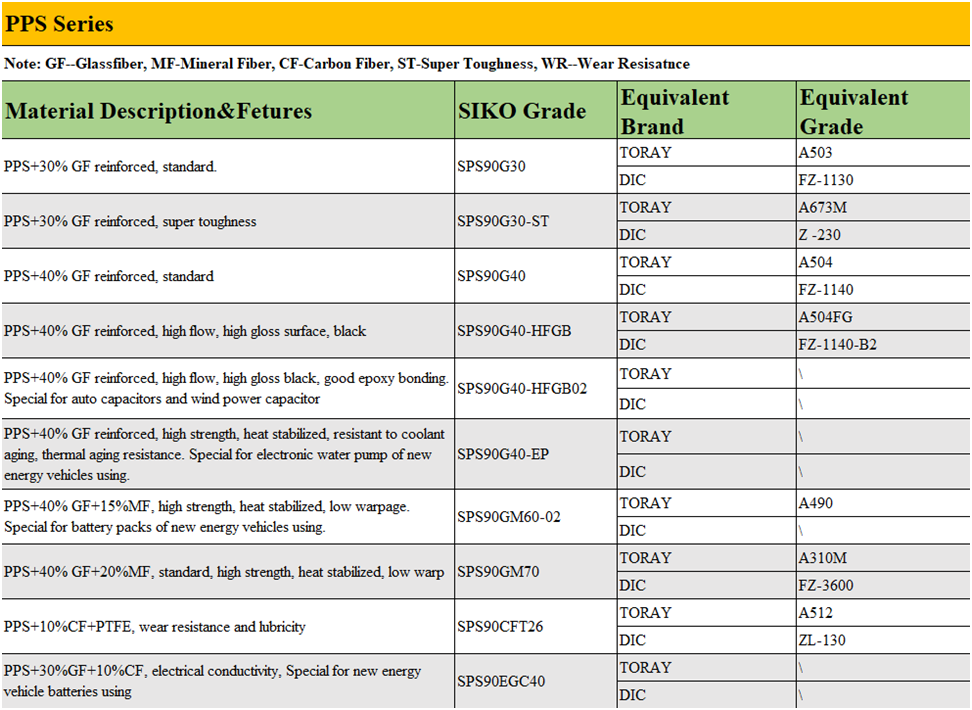

SIKOPOLYMERS’ Main grades of PPS and their equivalent brand and grade, as following:

As can be seen from the above table, SIKOPOLYMERS’ PPS has:

Better dimensional stability: lower deformation of parts under alternating hot and cold conditions

Lower water absorption: the lower the water absorption rate, the longer the product aging time higher strength and modulus stronger support and protection

Higher temperature resistance: better heat aging performance.

In addition, PPS has better process ability, lower processing energy and lower material costs.